Swipe to view more

Bar Sales

The widest stock of duplex and super duplex stainless steels anywhere, an extensive choice of stainless and nickel alloys, plus our unique Ferralium® 255 and Hiduron® alloys.

Find Out More

Swipe to view more

Plate Sales

We hold a complete range of duplex and super duplex stainless steel plates up to 3” thick, with water jet cutting available directly from our USA facility.

Find Out More

Swipe to view more

Piping Projects

We provide a full supply service for pipes, flanges and fittings, backed by our in-house services and expert team.

Find Out More

Swipe to view more

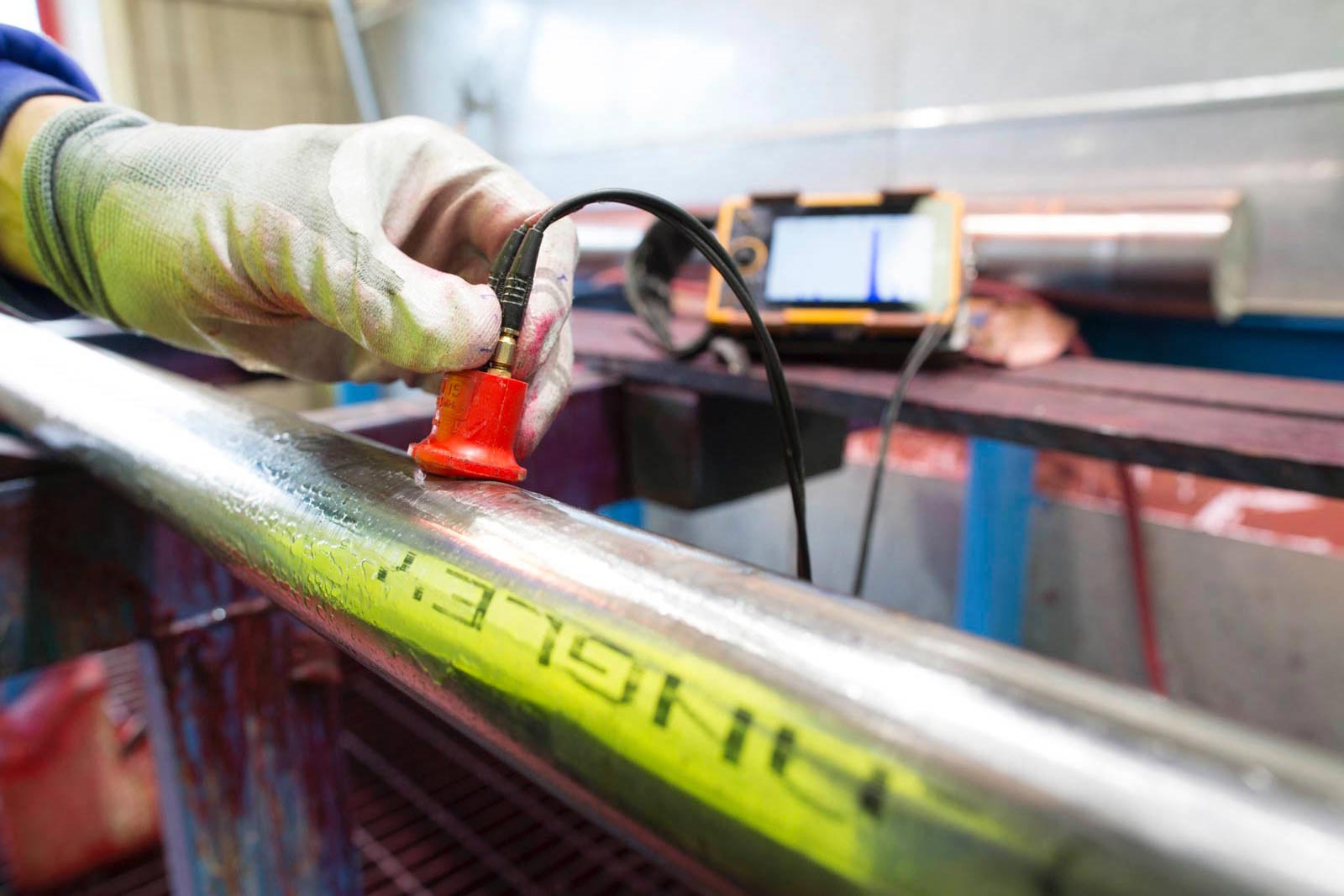

Services

Langley Alloys’ in-house inspection, testing and machining capabilities make us a single-source supplier, reducing your cost, time and effort.

Find Out More